In a new series, ‘Future of...’, we take a look at what is shaping the future of certain industries. Here, we look at the future of fuel and, specifically, the aviation industry. We look at the companies leading the way and the potential challenges that arise from creating such fuels.

Sustainable Aviation Fuel – now on the runway and about to take off…

Aviation currently contributes about 2.5% of global greenhouse gas emissions (GHGs) emissions. However, many more people are hopping onto planes post-pandemic and according to the International Energy Agency, the aviation industry is most definitely not on track to meet its GHG reduction targets. CO2 emissions from aviation did fall by a third from their 2019 level in the wake of the pandemic, but now, with passenger and cargo volumes set to rise, the aviation industry needs a whole range of solutions to tackle what will almost certainly involve rising emissions.

This is where sustainable aviation fuel (SAF) comes in. Although battery-electric and hydrogen-powered aircraft are being developed, the aviation industry will continue to rely on liquid fuels in the near future and most likely for some time to come. SAF is a ‘drop-in’ replacement for the kerosene currently burned by planes and offers an 80% lifecycle emissions reduction compared to conventional fuel.

What is sustainable aviation fuel (SAF)?

While fossil fuels take millions of years to produce, forming underground from organic matter, SAFs mimic these natural processes using renewable resources, and produce synthetic fuels in a fraction of the time. Synthetic fuels have the same properties as fossil fuels and are fully compatible with the existing global fuel infrastructure. They can be used in conventional internal combustion engines and jet engines, meaning that cars, planes, and ships can run on synthetic fuels without being changed or refitted. SAFs can also use the current fuel infrastructure for storage and distribution.

The first passenger flight partly fuelled by sustainable synthetic kerosene took off in February 2021. Airlines have already undertaken some 450,000 flights using SAFs as part of the fuel mix. The industry aims to be carbon neutral by 2050, and so far SAFs seem the only practical way to get there.

How are SAFs made?

All fuels are simply made up of hydrocarbon chains of different lengths. The base building block of a synthetic fuel is called syngas, a mixture of hydrogen (H) and carbon monoxide (CO). You need syngas to produce any type of liquid hydrocarbon fuel, such as jet fuel, diesel, or gasoline. Producing syngas requires a lot of energy and in order to be sustainable this energy needs to come from a renewable source.

What types of renewable synthetic fuels are there?

There are currently 3 ways of producing renewable syngas, and the resulting climate-friendly synthetic liquid fuels.

Biofuels from biomass

There are several ways of converting biomass into liquid fuel, but the most scalable and most versatile in terms of feedstock is through the gasification of biomass. This involves converting the biomass into syngas by heating it at very high temperatures. Biofuels can be produced from a variety of resources, also known as feedstocks. These include waste biomass such as used cooking oil; algae; or specifically grown energy crops such as sugarcane and corn. Biofuels produced by treating vegetable oils, waste oils and fats – Hydroprocessed Esters and Fatty Acids (HEFA) – are the only renewable synthetic fuels currently commercially available.

E-fuels from green hydrogen

E-fuels are produced from renewable electricity, such as solar, wind, or hydro power. The renewable electricity drives an electrolyser that splits water into hydrogen and oxygen. The resulting hydrogen is mixed with CO2 and turned into syngas during the process. Continuous renewable energy supply and electricity storage remain a challenge, but these power-to-liquid fuels are showing potential as drop-in SAFs.

Solar fuels from sunlight

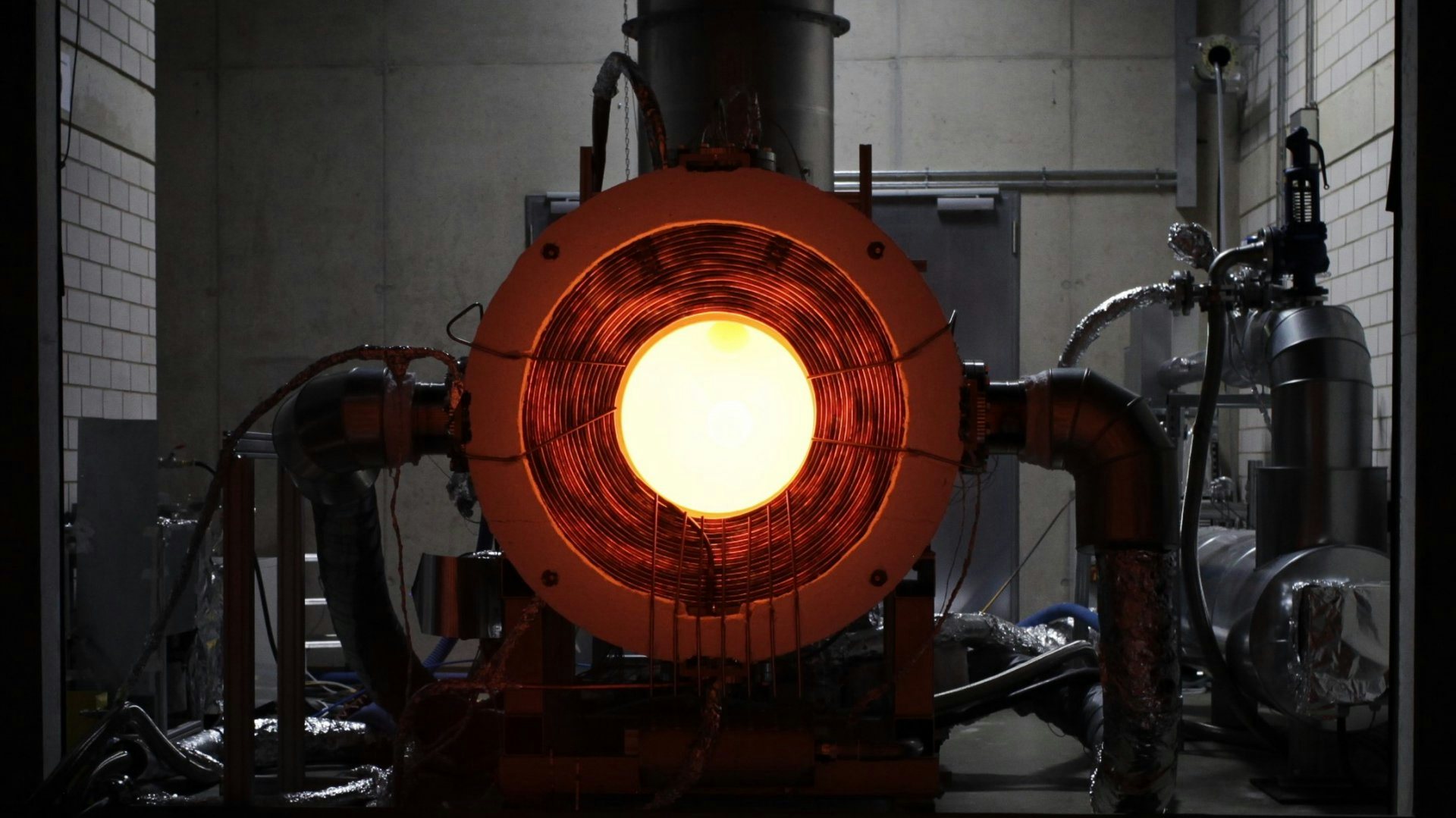

Solar fuels are produced from solar heat that drives a thermochemical reactor. In the reactor, carbon dioxide and water are converted into syngas. Inexpensive thermal energy storage in sunny climes means that solar fuels have the potential for being produced at scale. An independent study assessing the geographical potential concludes that solar fuels could cover 50 times the current global jet fuel demand.

Targets and initiatives

Although the fuel efficiency of fossil-based jet kerosene in international aviation has improved since 2010, progress has slowed in the last few years. Sustainable aviation fuels currently account for less than 0.1% of aviation fuel consumption and because of low production levels, SAFs still cost double conventional fuels. The International Air Transport Industry has set a target of reaching 2% by 2025.

In July the European Parliament voted to adopt draft rules for the ReFuelEU initiative, which aims to require sustainable aviation fuel to account for at least 85% of EU aviation fuel by 2050. Negotiations will now begin with member states on the final legislation to put this target into law. In the United States, the Sustainable Aviation Fuel Grand Challenge aims to scale up SAF production to 11 billion litres annually by 2030 and to eventually meet the country’s entire aviation fuel demand by 2050.

New tax credits for clean fuel production from the US Inflation Reduction Act, signed into law on 16 August, will serve to boost these companies further and faster, as SAF tax credits are an integral part of the Act. This critical legislative development in the US also follows the UK Government’s Department for Transport of its Jet Zero Strategy. This includes an ambition for a minimum of five commercial-scale SAF plants to be under construction in the UK by 2025, and a mandate for the equivalent of at least 10% SAF to be blended into conventional aviation fuel by 2030.

It’s not all plane sailing…

There is some controversy about what constitutes ‘sustainable’ aviation fuel though. There are concerns that food-and-feed based biofuels encourage the spread of oil-palm plantations and contribute to deforestation. Advanced and waste-based biofuels are generally preferred by environmentalists to their crop-based equivalents, but the raw materials needed are finite and difficult to scale up. Biomass is a pretty bulky material, which makes it expensive to gather, transport and store.

Something else to consider is that the aviation industry accounts for around 1.9% of global GHG emissions, while road transport is responsible for around 11.9%. If the ReFuelEU initiative is made law, waste fats will be channeled into the production of biogenic aviation fuels. Because of the more complex production process, evidence shows that the production of HEFA from waste fats is more energy-intensive and less efficient than biodiesel production for road and maritime transport from the same raw waste materials. Therefore channeling limited available waste fats away from producing fuel for road and maritime transport to fuel for the aviation sector may lead to a loss of potential GHG emission savings.

Now boarding!

Companies are leaping into the SAF market and starting to create sustainable aviation fuels at a much lower cost. On the e-fuels front, Norway – a country with plenty of hydro and wind power – is home to a consortium called Norsk e-Fuel, which is building a direct air capture (DAC) plant to produce SAF. They aim to start producing 12.5 million litres of fuel a year from 2024.

Another European player, Swiss firm Synhelion is leading the way in solar fuels. Their technology minimizes the number of energy conversion steps by using the solar heat directly to reverse the combustion process and turn water vapour and CO2 into fuel. Synhelion’s proprietary thermal energy storage, means the company can produce fuel around the clock, unlocking synthetic fuel production at prices that could soon be competitive with fossil fuels. They are currently building the world’s first industrial facility for the production of carbon-neutral solar fuel in Jülich, Germany and expect to start production in 2023. Their target, by 2040, is 50bn litres of SAF a year. With commercial jet fuel consumption cited at around 260bn litres in 2021, the outlook looks very promising.

Velocys is a spin-out company from Oxford University in the UK and the Pacific Northwest National Laboratory in the USA, are collaborating with British Airways to develop a full-scale commercial SAF plant in Immingham, UK. This is expected to be Europe’s first commercial scale waste-to-jet-fuel facility, processing household and commercial waste destined for landfill or incineration. Meanwhile Aemetis, founded in 2006, already produces sustainable aviation fuel and renewable diesel from the almond orchards and vineyards of California. They use gasification to create hydrogen, which is then combined with vegetable oil and animal fat to produce fuel.

This is just the beginning. Soon, sustainable aviation fuel will be taking off in a major way, scaling up to produce the synthetic fuels we need to radically cut CO2 emissions and meet our Paris Agreement goals.